Common Obstacles in Foam Control and How to Get rid of Them Successfully

Common Obstacles in Foam Control and How to Get rid of Them Successfully

Blog Article

The Function of Foam Control in Enhancing Product Top Quality and Performance

Foam control is an often-overlooked yet essential component in the search of product top quality and operational performance throughout diverse industries. By successfully handling foam formation, companies can not only improve the consistency of their formulations but additionally take on functional obstacles that can restrain performance. This conversation will explore the complex influence of foam on both item stability and production processes, elevating important inquiries about the strategies that can be used to maximize foam control. As we think about these ramifications, it ends up being clear that the risks are more than they could at first appear.

Comprehending Foam Formation

Foam development is a complex sensation that can considerably impact item high quality and functional efficiency across various industries. Recognizing these variables is essential for taking care of foam successfully.

The liquid's thickness and surface stress play essential roles in foam stability. Surfactants, for example, can minimize surface tension, advertising bubble development however likewise boosting foam security, which can be problematic in specific applications. Moreover, mechanical anxiety, temperature level fluctuations, and the existence of impurities can aggravate foam generation, making it necessary to check these elements throughout manufacturing processes.

Industries such as food and beverage, pharmaceuticals, and chemical manufacturing need to be particularly watchful pertaining to foam control. By realizing the underlying devices of foam development, companies can implement targeted methods to reduce its impacts, thereby maintaining operational efficiency and guaranteeing consistent item performance.

Influence On Item Quality

The presence of foam can considerably compromise product top quality across numerous sectors. In manufacturing processes such as food and beverage, pharmaceuticals, and cosmetics, extreme foam can lead to inconsistent product formulations. In food production, foam may catch air, influencing appearance and flavor, which can ultimately modify customer perception and fulfillment.

Furthermore, foam can prevent the harmony of finishings and paints, resulting in defects like bubbles and irregular coatings. In pharmaceutical applications, foam can hinder the accurate application of liquid medicines, possibly impacting therapeutic efficacy and individual safety and security. These high quality problems not only diminish the end item's allure but can additionally cause pricey recalls and damage to brand reputation.

Additionally, the presence of foam can make complex high quality control steps, making it challenging to attain specific dimensions and constant results. Effective foam control not only reduces these threats but additionally boosts general product high quality by making certain that formulations meet strict industry requirements. By purchasing foam control techniques, firms can guard their products, boost consumer satisfaction, and keep a competitive edge in the market.

Operational Obstacles From Foam

Efficient procedures in different sectors can be badly interrupted by the presence of foam, which poses multiple challenges throughout production procedures. Foam can prevent mixing and response times, impeding the efficiency of chemical processes. In sectors such as food and beverage, foam formation can cause unreliable fill degrees, resulting in item waste and variances in product packaging.

In environments where hygiene is extremely important, such as pharmaceuticals and food processing, foam can complicate cleaning methods, producing covert tanks for contaminants. This not only elevates top quality worries yet likewise can result in compliance issues with regulative criteria.

Furthermore, the mental impact on drivers can not be neglected; extreme foam can produce a chaotic workplace, resulting in decreased morale and productivity. In recap, resolving the functional difficulties positioned by foam is important to preserving effectiveness and product quality in various sectors.

Approaches for Reliable Foam Control

Exactly how can industries effectively mitigate the difficulties posed by foam? Efficient foam control techniques are essential for improving item quality and functional effectiveness.

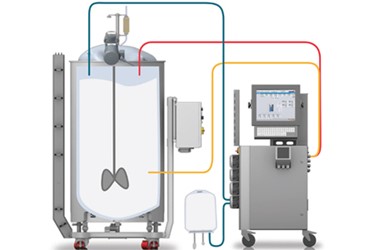

Along with chemical services, procedure optimization plays an important duty in foam management. Industries can analyze and readjust criteria such as mixing stress, temperature, and speed to decrease foam generation. Implementing equipment modifications, like mounting foam-breaking gadgets or adjusting tank design, can even more help in reducing foam degrees.

Regular tracking and analysis of foam habits within manufacturing procedures are likewise crucial. Making use of innovative sensing units and analytics can give real-time information, permitting for timely interventions and modifications. Team training is equally vital; Get the facts ensuring that employees are knowledgeable concerning foam dynamics and control strategies can lead to proactive foam management.

Study and Sector Applications

While many industries face unique challenges connected to foam control, study expose that tailored methods can substantially improve both product quality and functional effectiveness. In the pharmaceutical industry, for instance, a leading maker carried out a customized foam control strategy that reduced foam development throughout fermentation processes. This development not just enhanced yield by 15% but additionally lessened contamination risks, ensuring greater product honesty.

In a similar way, in the food and beverage sector, a major dairy manufacturer faced too much foam during pasteurization - Foam Control. By introducing a specialized antifoam representative, they reduced processing time by 20%, which straight equated to enhanced throughput and reduced power consumption. The application of foam control measures ensured regular product appearance and taste, reinforcing brand name loyalty

In the chemical manufacturing market, a study highlighted the effective application of foam control in wastewater treatment processes. The implementation of a real-time tracking system allowed drivers to adjust antifoam dosage dynamically, bring about a 30% reduction in chemical use and improved effluent high quality.

These study illustrate the varied applications of foam control across sectors, highlighting its essential function in boosting product high quality and operational performance.

Conclusion

To conclude, effective foam control is important to boosting product high quality and functional performance throughout various sectors. By resolving foam development, companies can minimize the adverse effect on formulations, structure, and application accuracy. Carrying out targeted foam administration approaches not just lowers processing delays and waste however likewise boosts tools integrity. Ultimately, prioritizing foam control adds to improved productivity, helpful hints protecting brand track record, and boosting consumer satisfaction, highlighting its significance in quality assurance within manufacturing processes.

Foam control is an often-overlooked yet important part in the pursuit of item top quality and operational efficiency throughout varied markets. Staff training is just as crucial; making sure that workers are educated regarding foam dynamics and control methods can lead to positive foam management.

While several markets deal with distinct challenges connected to foam control, case researches expose that tailored techniques can considerably boost both item top quality and functional efficiency (Foam Control). In the pharmaceutical sector, for circumstances, a leading producer executed a customized foam control strategy that minimized foam formation throughout fermentation procedures.In final thought, reliable foam control is essential to boosting product high quality and operational effectiveness throughout different sectors

Report this page